High volume machining is the foundation for companies that want to respond to emerging market demands with speed, precision, and cost effectiveness in today's hyper-competitive industrial environment. Whether you're offering automotive parts, aerospace components, or medical devices, consistently producing large batches of high quality components is absolutely essential.

At Falcon CNC Machining we specialize in high volume manufacturing solutions applying the latest technology combined with quality craftsmanship. Let's take a look at what high volume machining is, where it comes from, and how it compares to other production technologies.

What Is High Volume Manufacturing?

High volume manufacturing basically means producing a very large number of parts or products in a specified time with consistency, scale, and efficiency - even thousands or millions of items of the same unit!

High volume production is commonly used in industries such as:

Automotive manufacturing

Aerospace and defense

Consumer electronics

Medical device manufacturing

Industrial products

These industries all rely on high volume production capabilities in order to compete with strict timelines and prices while adhering to quality standards.

Is CNC Machining a High Volume Manufacturing Process?

That's a huge YES - when set up appropriately.

Traditionally, CNC machining has been pitched as a low to mid volume prototyping manufacturing solution.The positive advancements of automation, tooling, and programming have made CNC machining a viable option for high volume production.

Three main reasons CNC technology is viable for high volume manufacturing:

Repeatable Accuracy: CNC machines produce parts consistently within microns of tolerance, time and time again over thousands of parts.

Automation Integration: Robotic arms, tooling data monitoring systems, and pallet changers, among others, are workable for lights-out machining (overnight, unattended, production).

Flexible Scale: There exist adjustability to produce as little as 10 parts and expand to 100,000 with minimal investment and variation or delays.

At Falcon CNC Machining, we use multi-axis CNC machines with smart production planning software to make sure high volume projects are produced efficiently and flawlessly.

What Are High Volume Production Processes?

There are many manufacturing processes that people can commonly employ for achieving high volume production, including:

CNC Machining: High tolerance, precision parts which thrive on repeatable consistency.

Injection Molding: ready for mass production of plastic parts.

Die Casting: High volume production of metal parts with complex geometries.

Stamping and Punching: High speed sheet metal methods.

Additive Manufacturing (3D Printing): Popping up in low/medium quantities, especially applicable for complex, high-strength lightweight designs.

Depending on the project requirements (material, complexity, volume) you could mix several production processes for an efficient manufacturing flow.

High Volume Production vs. Low Volume Production: What Are The Differences?Though both high and low volume production share an emphasis for quality & efficiency there are important differences

| Feature | High Volume Production | Low Volume Production |

| Quantity | thousands to millions | 1 to several thousands |

| Setup costs | high (but offset by scale) | low |

| Customization | limited (standardization favored) | very flexible |

| Production | very fast following set up | slower, but flexible |

In summary: High volume, high output emphasis with a low cost per unit approach, low volume means flexibility and customization.

What Processes Are High Volume Production?

Firms who can not afford to compromise efficiency and scale will use:

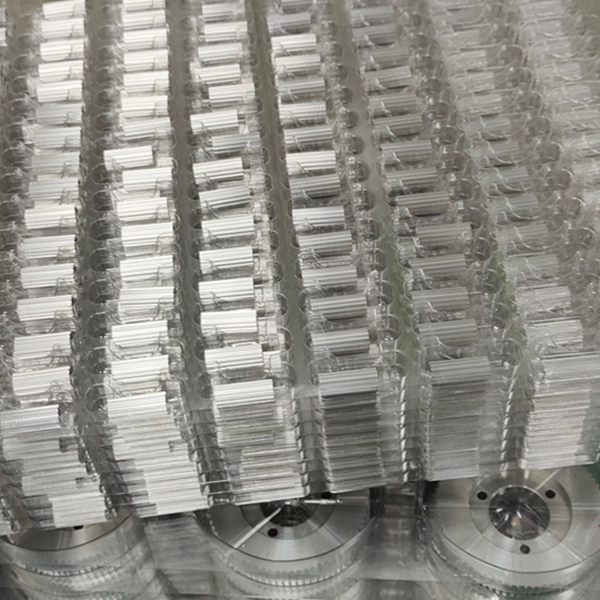

Multi-Spindle CNC Machining. Machines that can cut multiple parts simultaneously. Decreasing the time required to manufacture all the parts.

Automated Production Lines. Automated cells where from one automated loading through to automated inspection integrates all the manufacturing steps

High Speed milling/Turning machine centers. Machines are useable solely for efficiency, engineered to reduce cycle-times while maintaining accuracy.

Continuous Flow Manufacturing. and Integrated manufacturing and Simplification Steps improve workflow and consequently cycle time

At Falcon CNC Machining we utilize all of these technologies in a way that improves both productivity and quality for every high volume project.

Why should you choose Falcon CNC Machining for your High Volume Machining Projects?

Making the right decision in your high volume production partner can be the difference between the success or failure of your project. top companies trust us for the following reasons:

Years of Experience: Delivering high volume, high precision CNC parts.

Latest Equipment: 5-Axis and multi-spindle CNC machines ready for mass production.

Flexible Capacity/Scalability: Able to scale capacity based on the needs of your project.

Quality Control: ISO certified processes to ensure that each and every part is built to your specifications.

Fast Turnarounds: Faster production cycles without sacrificing quality.

Confidence in Your Transition to Mass Production?

At Falcon CNC Machining, we know that in today’s competitive markets, quality and speed are no longer an option; they are expected. If you are ready to take your project from prototype to high volume production with total confidence, we invite you to discuss our high-volume machining solutions with us today.