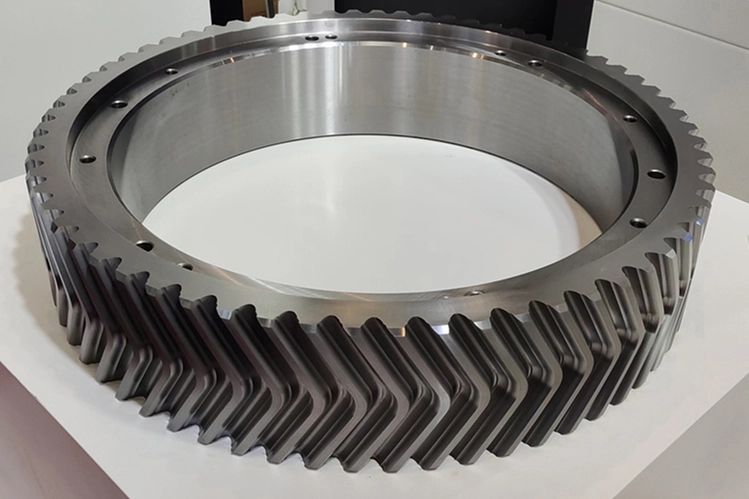

Unlock precision and durability with Falcon MFG's stainless steel machining services. Our CNC expertise transforms stainless steel into high-performance components, harnessing the material's corrosion resistance, strength, and versatility. From medical devices to architectural elements, our state-of-the-art facilities and skilled team ensure top-tier quality. Proficient in machining various grades like 304, 316, and 17-4, we tailor components to meet stringent industry standards. Falcon MFG stands as a trusted partner for stainless steel machining, delivering reliability and precision across diverse applications. Elevate your projects with components that combine the resilience of stainless steel with Falcon's unparalleled machining capabilities.

Stainless steel alloys shine in CNC machining, offering a harmonious blend of corrosion resistance, strength, and versatility. Falcon MFG maximizes these advantages, delivering precision components that endure harsh environments. Whether using 304 for general applications, 316 for enhanced corrosion resistance, or 17-4 for strength and durability, our CNC machining prowess transforms stainless steel alloys into reliable components. Trust Falcon MFG for stainless steel machining that adheres to the highest industry standards, ensuring enduring quality and performance in diverse applications.

Falcon MFG excels in stainless steel machining, specializing in grades such as 304, 316, and 17-4. Our skilled team crafts high-quality components with superior finishes for diverse industrial applications.

304 (A2): General-purpose stainless steel with excellent corrosion resistance.

316 (A4): Offers superior corrosion resistance, particularly in harsh environments.

17-4 (PH): Known for its high strength and corrosion resistance.

Electropolishing: Enhances corrosion resistance and provides a smooth, reflective finish.

Passivation: Removes impurities and enhances corrosion resistance.

Brushed Finish: Creates a textured appearance.

Medical Instruments: Precision components for medical devices.

Architectural Elements: Stainless steel parts for aesthetic and structural applications.

Industrial Components: Tailored for strength and durability in diverse industrial settings.

Call

Address

#41 Jinlei Industrial Zone, Xiaotang Road, Youganpu, Fenggang, Dongguan